Slip ring assemblies

Whether applied in car, ship or tower cranes, wind turbines or treatment plants, in machine tools or printing machinery, various industrial applications, or safety technology: The list is long and we develop slip rings meeting any requirements and suited to any customer´s requests. With over sixty years of experience in developing, planning and manufacturing, we are able to develop the right solution for any application and requirement in both small batches of only one right up to industrial mass production.

Ensuring the ideal transfer of power, signals and data from a static to a rotating component demands special technical expertise and pronounced practical know-how. Building on this foundation, we can offer a range of standard components which can be assembled according to specification or even supplemented by new components.

This saves costs for our customer and significantly accelerates the planning and manufacturing of new slip rings. Additionally we are able to develop completely new solutions right down to the details of each individual component.

Wether the product is supposed to implement specific functionalities or meet particular requirements in robustness, reliability or safety, we will find the most suitable solution to meet our clients´ unique requests – even for more complex demands or very challenging conditions.

Contacting Systems

Non-Contacting Systems

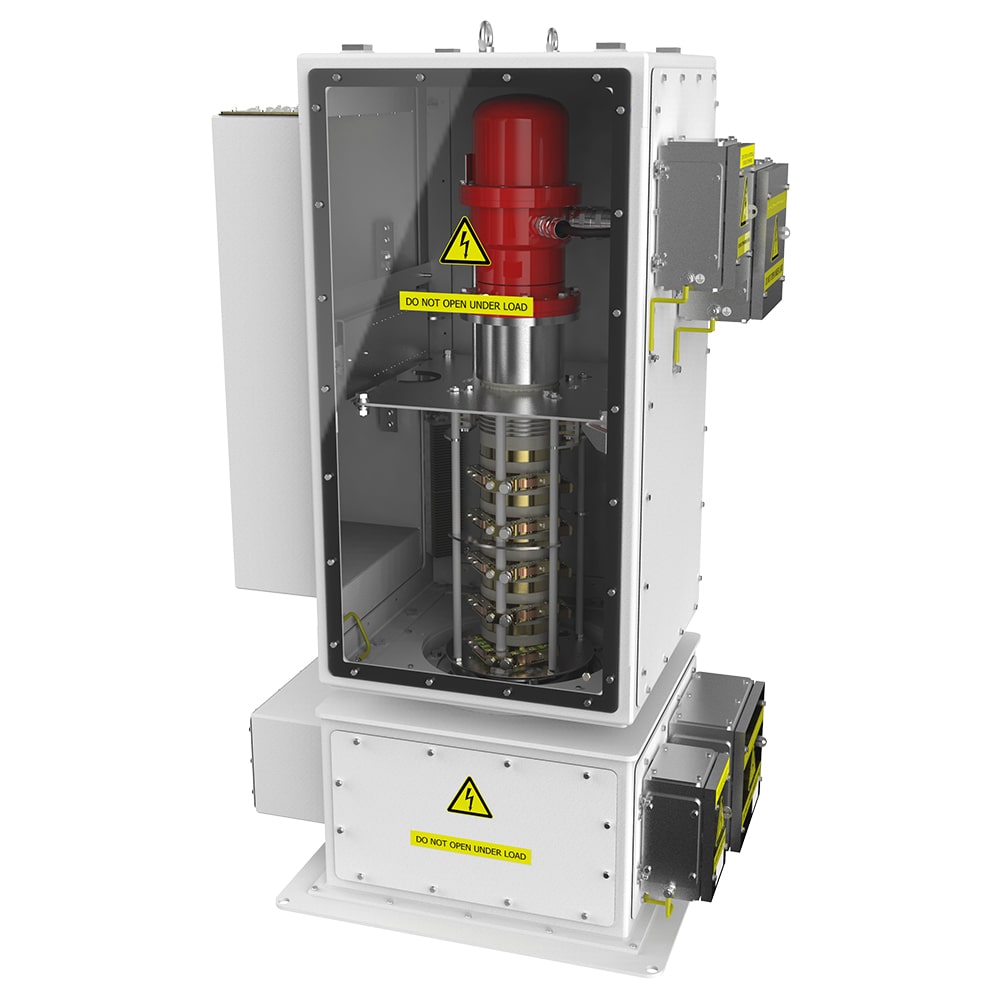

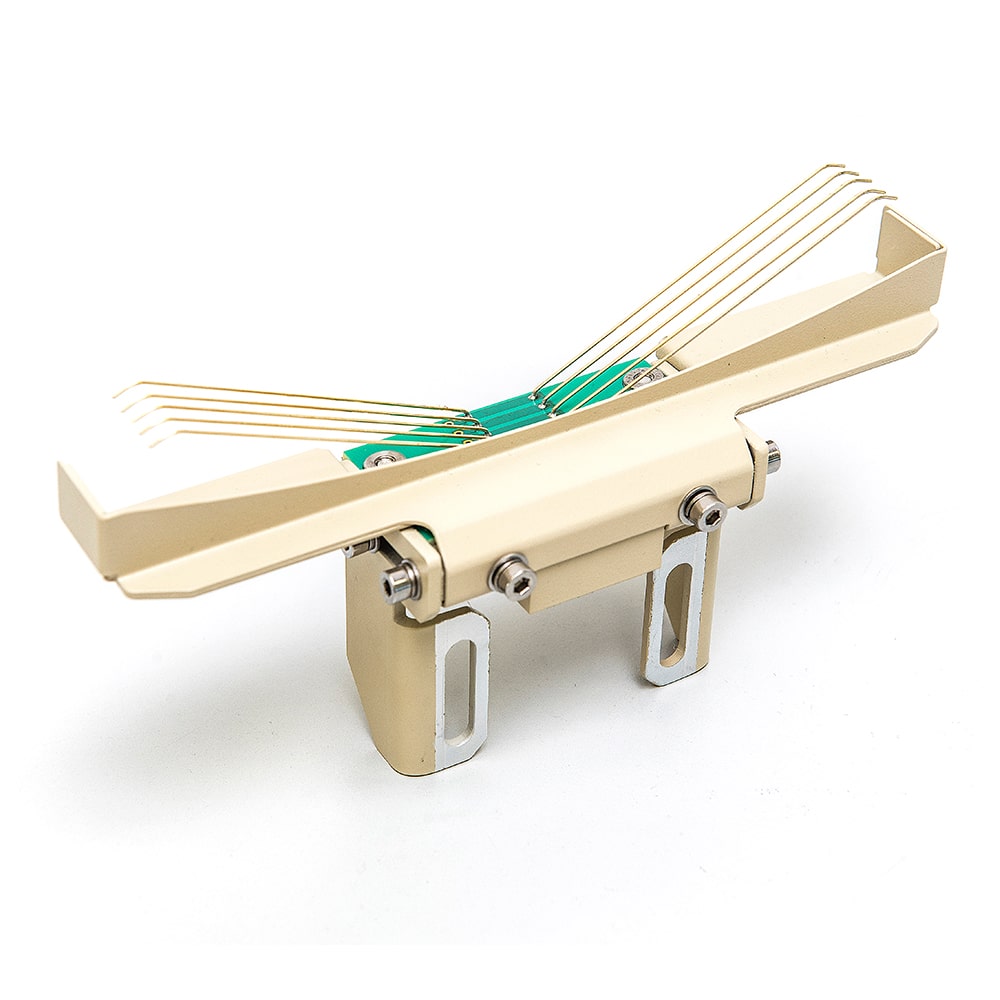

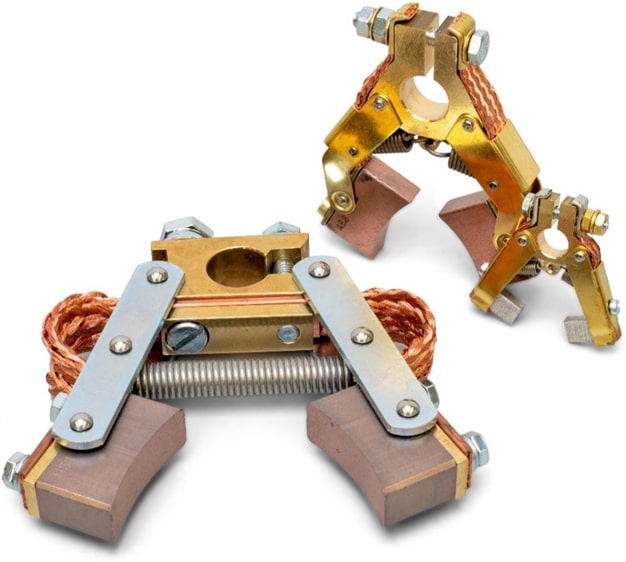

Graphite brushes

For higher currents (in the power section) the use of graphite brushes has proven to be the most cost-efficient and thus most suitable solution.

Depending on application, as well as electrical, mechanical and environmental requirements the most suitable graphite brushes are used comprising of either copper graphite or silver graphite.

Technical Parameters:

- Rotational speed:

- 1 up to 3000 rpm

- Digital transfer:

- 10 Mbit/s,

- CAN-Bus, Profi-Bus

- Current rating:

- mA up o 6 000 A

- Voltage rating:

- mV up to 25kV

- graphite contacts exchangeable

- Quick maintenance

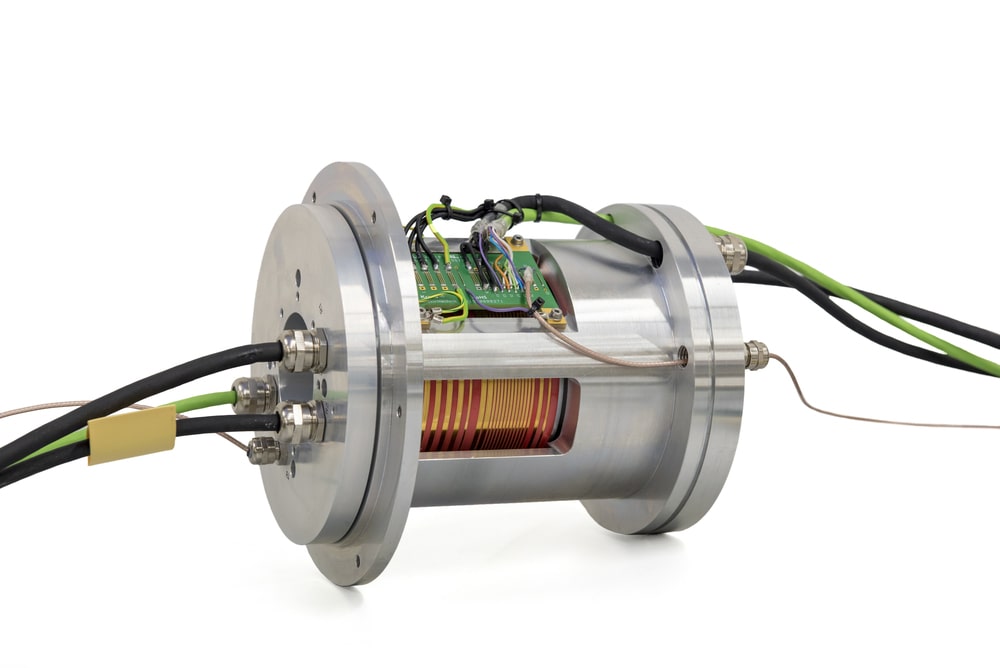

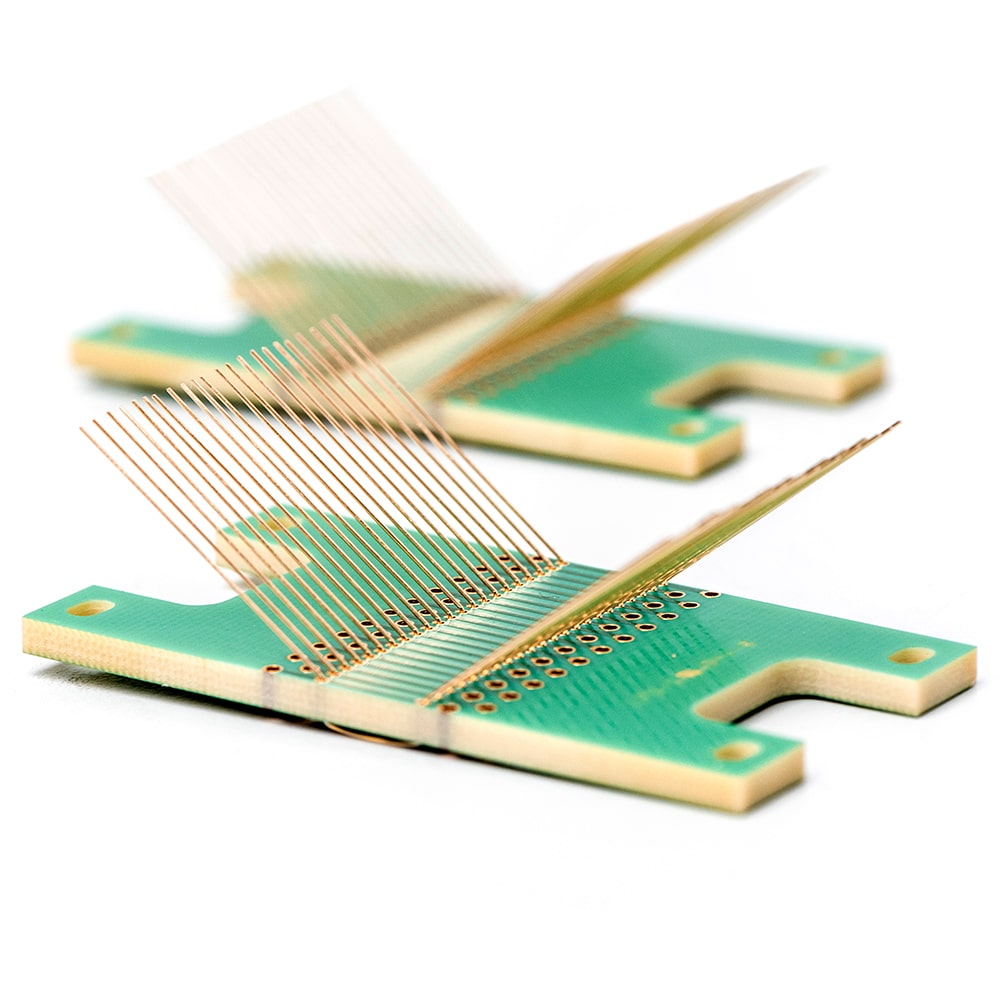

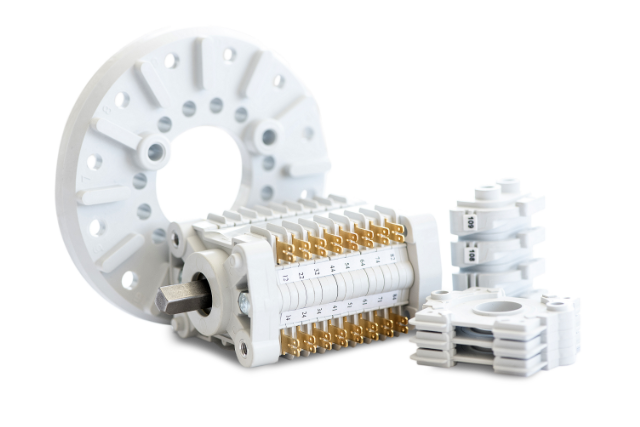

Multi Wire System

This Technology is especially suitable for continuously running applications.

It is applied in high transmission systems and runs free of maintenance.

Technical Parameters:

- Contact points per sliding contact:

- 20

- Quantity of contacts:

- 1 up to 200

- Contact noise:

- < 40 mOhm

- CAN-Bus, Profi-Bus, Device Net, 1 Gbit Ethernet, etc.

- Current rating:

- mA up to160 A

- Voltage rating:

- mV up to 1.000 V

- Maintenance free / no oiling required

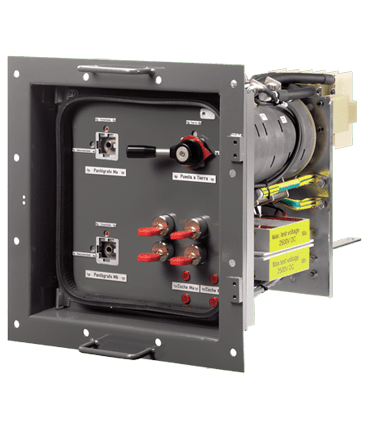

Standard Systems

In these simple units the single slip ring components are being stacked onto another. As far as possible each component is standardized to keep a certain level of competitiveness. Still the design can be easily adapted according to customer´s needs.

The standard system is a simple and cost-efficient solution, fulfilling harsh environmental requirements thanks to the durable construction.

Technical Parameters:

- Rotational speed:

- up to 20 rpm

- Digital transfer:

- up tp 100Mbit/s

- Quantity of contacts:

- 1 up to 100

- Contact noise:

- < 20mV

- CAN-Bus, Profi-Bus, 1 Gbit Ethernet, RS422, etc.

- Current rating:

- mA up to 100A

- Voltage rating:

- mV up to 1.500V

- IP level to customer specification:

- IP44 – IP67

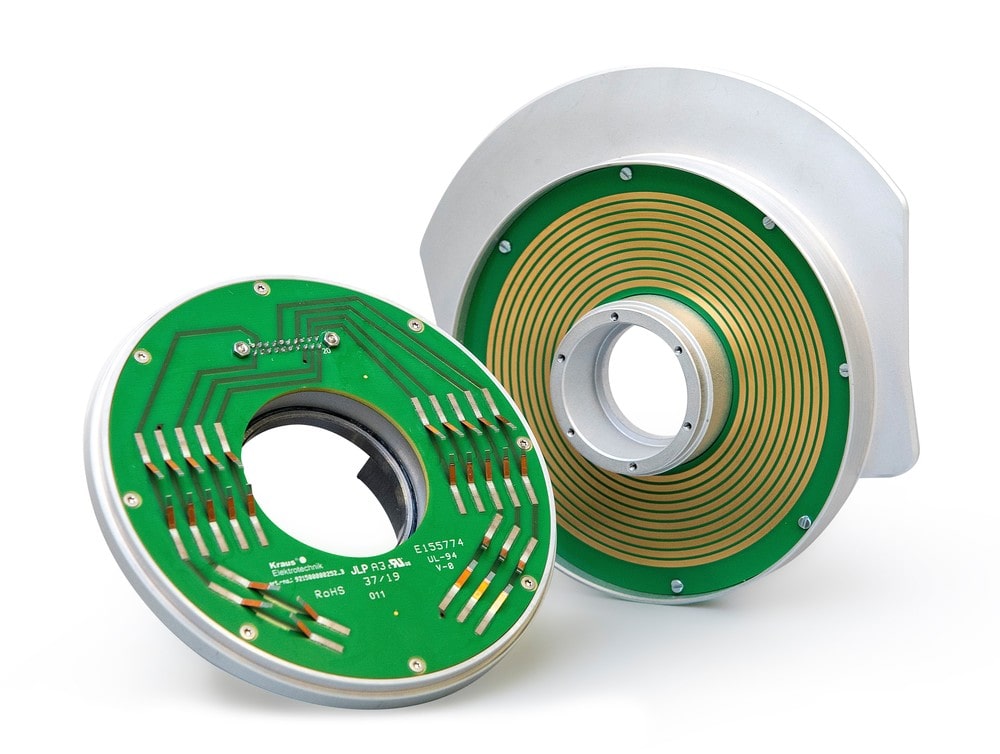

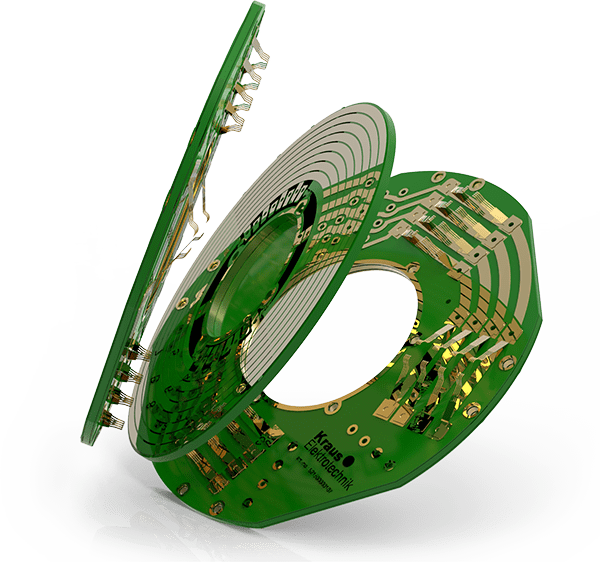

Pancake Layout

For constructions with limited space and where low contact noise is required we combine radial slip ring modules with multi wire technology.

With the space saving design of the so called “Pancake” system the tracks are not stacked onto each other as with the level by level system. They are fitted next to each other on a board occupying only a fraction of the space.

Depending on the customer´s requirements several boards may be fitted in one unit.

Technical Parameters:

- Coaxial high frequency transfer:

- 50 Ohm and 75 Ohm

- Low VSWR (Voltage Standing Wave Ratio) and insertion loss (depending on cable)

- Ethernet and Gigabit Ethernet:

- 100Mbit – 1Gbit

- Contact noise:

- 5 up to 30 mOhm

- CAN-Bus, Profi-Bus, Ethernet, RS422 & transmission of analogue and digital video signals (HD-SDI)

- Current rating:

- mA up to 10A

- Voltage rating:

- mV up to 400V

- Maintenance free up to 50 million rotations

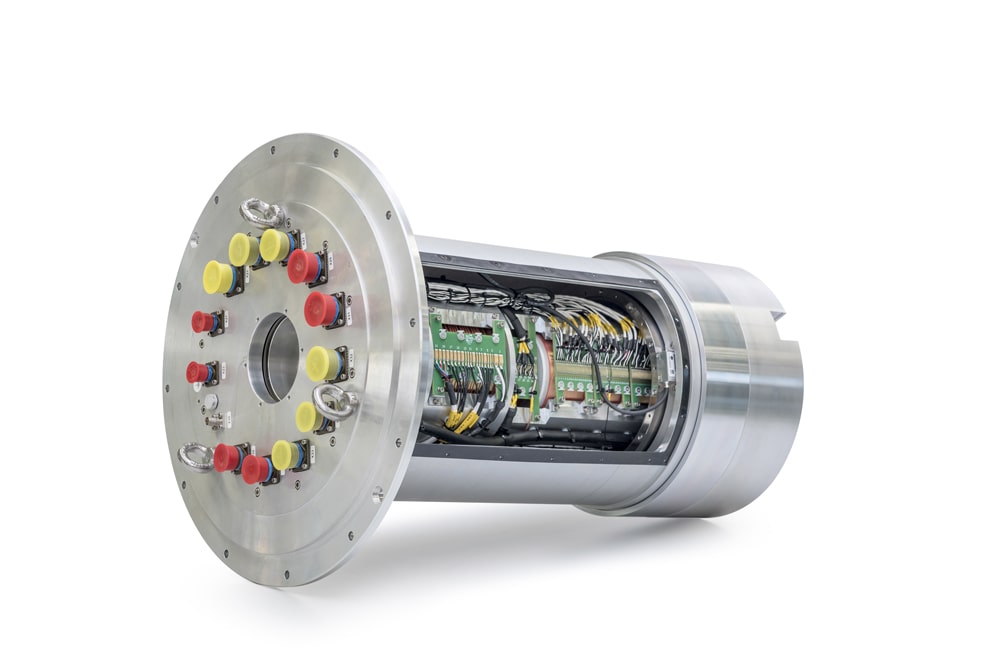

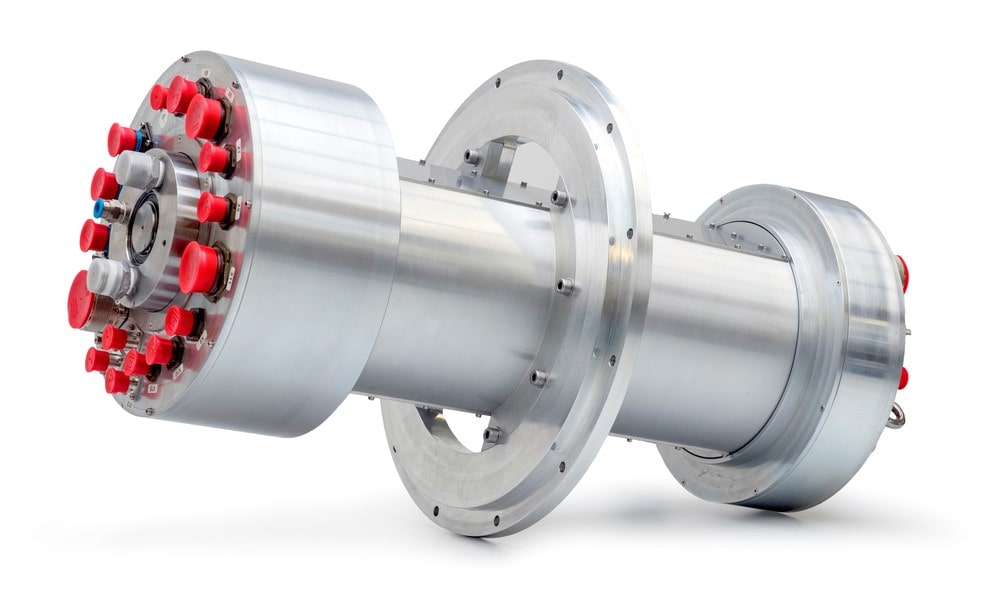

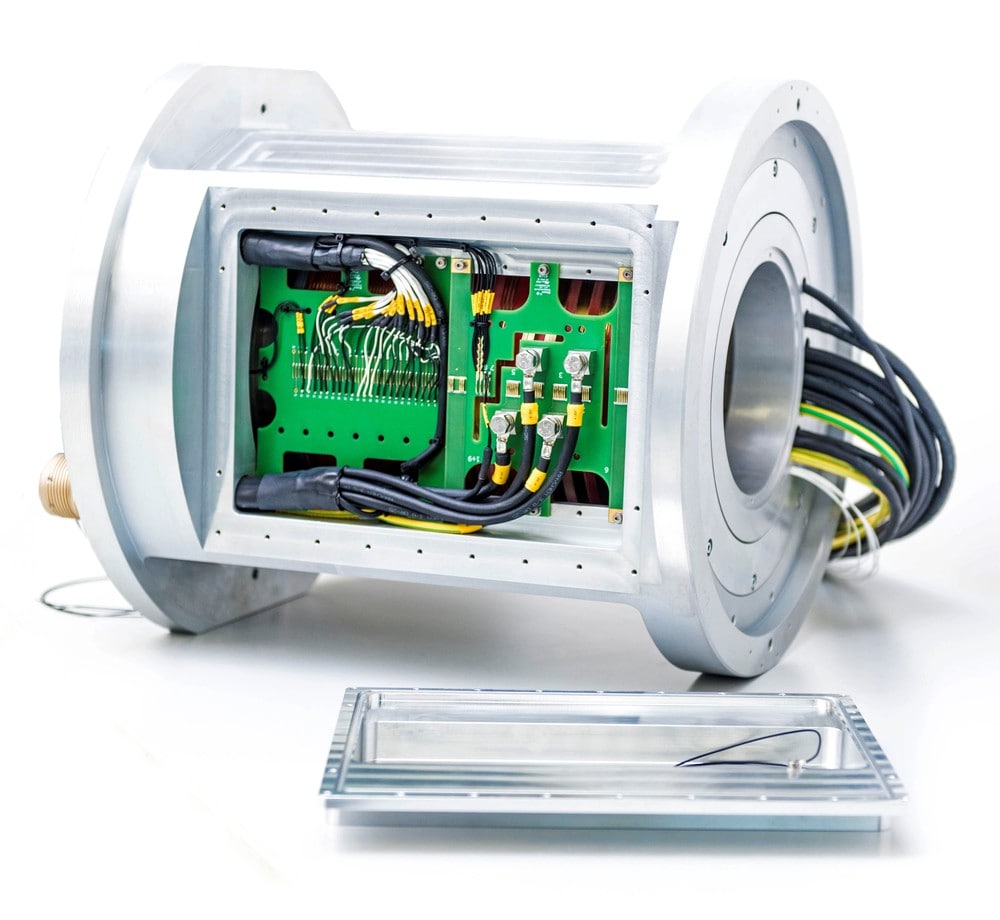

Cast modules

For high-tech applications and systems where space is a major issue Kraus provides slip ring units with cast modules.

The modules are manufactured with the centrifugal casting technology, i.e. the modules with inserted tracks are filled with epoxy resin according to an accurate process.

After the molding one or several V-shaped grooves are lathed into each track. The advantage of the V-grooves is the increased tolerance to mechanical vibrations and shocks and a reduced contact resistance.

Special gold plating

When the tracks have been machined into the right tolerances, the module is electroplated; the choice of electroplating process depends on the individual properties of the signal or power passing through, as well as factors such as transmission requirements, rotational speed, lifetime, cost etc.

Technical Parameters:

- Coaxial high frequency transfer:

- 50 Ohm and 75 Ohm

- Low VSWR (Voltage Standing Wave Ratio) and insertion loss (depending on cable)

- Transmission of analogue and digital video signals:

- up to 1,5 Gbit/s

- Rotational speed:

- up to high-speed applications

- Number of contacts:

- 1 – 500

- Contact noise:

- 5 up to 30 mOhm

- Up to 1,5Gbit HD-SDI, CAN-Bus, Profi-Bus, RS422, etc.

- Ethernet and Gigabit Ethernet:

- 100 Mbit – 1 Gbit

- High EMC protection according to international standard

- Current rating:

- mA up to kA

- Voltage rating:

- mV up to kV

- IP level to customer specification:

- up to IP 69K

Fiber Optic Rotary Joints (FORJs)

To transmit high data rates from a rotary to a stationary part non-contacting / optical transmission through fiber glass or synthetic fiber is a suitable solution. Due to the high EMC-protection these rotary joints may be applicable in EMC applications as well as welding systems. The optical solution enables a interference free transmission.

Both single mode (SM) and multi mode (MM) are available in single and multi-channel options. If more than two fibers are present in a system, multiplexing solutions can be offered upon request.

Technical Parameters:

- Rotation:

- up to 10.000 rpm

- Number of channels:

- up to 52

- Wave length:

- 1310 nm / 1550 nm (SM)

850 nm / 1300 nm (MM) - Fiber type:

- E9/125 (SM)

50/125 or 62.5/125 (MM) - Operating temperature:

- -40°C up to +85°C

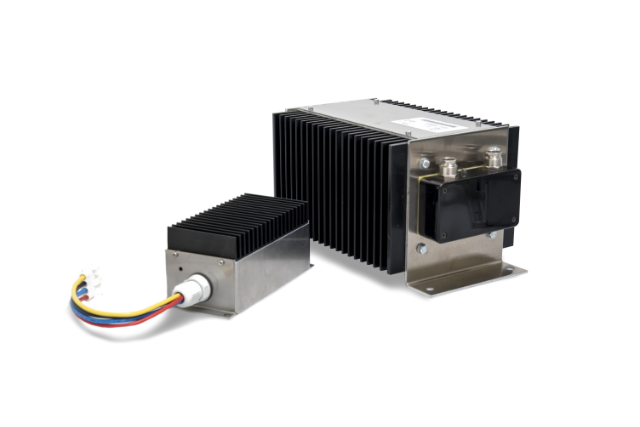

Non-contacting transmission (capacitive link)

Additional component for standard signal and data transmission.

The rotary joint enables a non contacting and steady transmission of high data rates at high rotational speed regardless the direction of rotation.

Technical Parameters:

- Rotation:

- max. 3.000 rpm

- Number of channels:

- up to 3

- Operating temperature:

- -30°C up to +70°C

- Gigabit Ethernet:

- up to 1Gbit

- High EMC protection according to international standard